Professional Steel Dealing With Solutions for Solid and Durable Frameworks

The function of specialist steel fixing remedies is crucial in the building of durable and solid frameworks, as they ensure the exact positioning and safe fastening of reinforcement bars. Understanding the potential challenges and crucial benefits connected with steel taking care of can significantly influence project end results.

Importance of Steel Dealing With

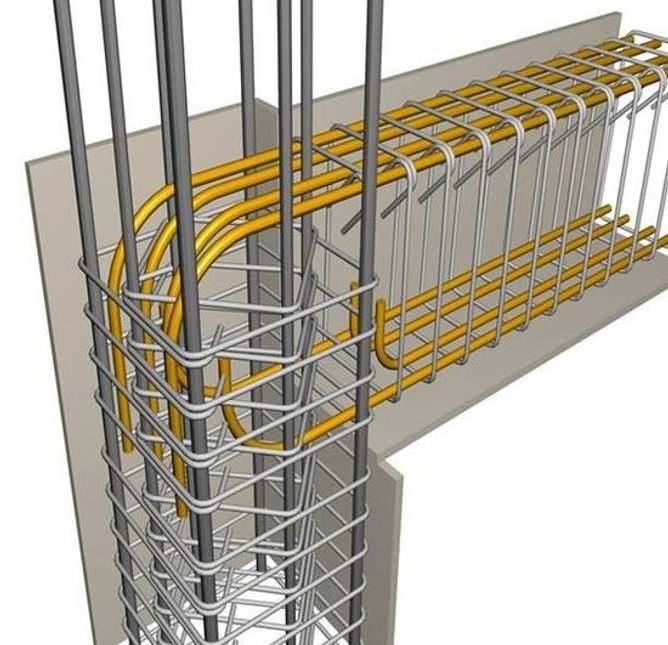

Steel repairing is fundamentally vital in the construction sector, as it ensures the structural integrity and longevity of reinforced concrete components. The process entails the mindful placement and binding of steel support bars (rebar) within concrete, which dramatically improves the load-bearing capacity and resistance to tensile forces. Without correct steel repairing, concrete structures are prone to breaking, settling, and ultimately failing under used loads, bring about costly repair services and possible hazards.

Furthermore, steel repairing adds to the overall design adaptability, allowing architects and engineers to produce complex frameworks that fulfill particular practical and aesthetic demands. Making use of steel reinforcement not only raises the life-span of concrete aspects however additionally lowers upkeep costs over time, making it a sensible investment for any type of building task.

Furthermore, adherence to industry requirements and regulations in steel fixing methods makes sure compliance with security protocols, thereby securing both workers future and on-site passengers of the structure. Altogether, the significance of steel repairing prolongs beyond simple building; it plays an essential role in improving security, durability, and efficiency, strengthening its condition as a vital component of contemporary building and construction methodologies.

Key Techniques in Steel Fixing

Efficient steel fixing counts on a range of techniques that boost the stability and efficiency of enhanced concrete structures. One basic technique is the exact placement of rebars, making certain that they are located according to comprehensive design specs. This consists of sticking to proper cover demands to protect steel from rust and preserve structural integrity.

Correct welding and mechanical couplers are also important in joining rebar sections, supplying a continuous load path throughout the structure - steel fixing. The choice of couplers need to be lined up with job requirements to ensure ideal toughness

Finally, complete assessment and quality assurance throughout the steel taking care of process are vital. Regular checks must be conducted to verify that all techniques are applied properly, ensuring that the final structure abides by safety and security standards and design requirements. These essential techniques jointly contribute to the overall effectiveness and durability of strengthened concrete building and constructions.

Advantages of Specialist Steel Correcting

When thinking about building and construction tasks, one can not ignore the substantial advantages of utilizing specialist steel dealing with solutions. Expert steel fixers possess specialized expertise and abilities that make certain the exact setup of steel support. This knowledge straight adds to the architectural integrity of buildings, bridges, and other framework, inevitably improving security and longevity.

Furthermore, professional steel taking care of services comply with sector requirements and policies, minimizing the threats of non-compliance. This not only protects the task from possible legal issues yet additionally ensures that the building and construction satisfies safety standards. Furthermore, Discover More seasoned steel fixers my sources use sophisticated strategies and devices, which causes improved performance in the construction procedure. This effectiveness can convert to set you back financial savings and timely job conclusion.

Typical Obstacles and Solutions

In building and construction jobs, numerous challenges can arise during the steel repairing process, affecting both timelines and architectural quality. One common issue is the imbalance of steel bars, which can result in structural weaknesses and demand rework. To minimize this, accurate measurements and normal examinations have to be conducted throughout the setup phase.

An additional difficulty is the capacity for rust, particularly in environments with high dampness or exposure to chemicals. Using corrosion-resistant products and applying protective coatings can considerably expand the life-span of the steel structure. Additionally, ensuring proper drainage can assist reduce water buildup.

Labor shortages and ability voids in the workforce existing an additional hurdle, typically resulting in hold-ups and inconsistent top quality. Buying training programs and employing knowledgeable experts can boost the skill collection of the crew and enhance general efficiency.

Finally, website constraints, such as Full Article minimal accessibility or room, can make complex the steel fixing process. steel fixing. Using modular construction methods or prefabrication can minimize these concerns by enabling elements to be assembled off-site, hence streamlining the installment process

Addressing these obstacles with proactive services guarantees that the steel dealing with procedure adds favorably to the task's success.

Future Trends in Steel Repairing

As the building and construction market remains to evolve, the future of steel fixing is poised to embrace innovative modern technologies and methodologies that enhance performance and safety. One significant trend is the assimilation of automation and robotics in steel taking care of processes. Automated systems can streamline the positioning and tying of rebar, minimizing labor expenses and decreasing human error.

Additionally, advancements in Building Information Modeling (BIM) are changing just how steel dealing with is intended and performed (steel fixing). BIM permits exact visualization of structural parts, promoting far better sychronisation among various professions and ensuring accurate installment of support products

Sustainability is additionally becoming a crucial emphasis in steel repairing methods. The usage of high-strength, light-weight products and ecologically friendly coverings is anticipated to rise, adding to minimized product waste and power usage.

Moreover, the adoption of smart modern technologies, such as sensors and IoT tools, will enable real-time tracking of structural honesty. This proactive method to maintenance will improve the longevity of frameworks and boost safety criteria.

Final Thought

In final thought, specialist steel fixing remedies are crucial for the stability and durability of strengthened concrete frameworks. As the area advances, proceeded innovations in steel fixing practices will certainly further contribute to the growth of safer, much more resilient framework, ultimately benefiting culture as a whole.

The role of professional steel fixing remedies is pivotal in the construction of solid and long lasting structures, as they make sure the exact positioning and protected fastening of reinforcement bars.Steel repairing is fundamentally crucial in the construction industry, as it ensures the structural honesty and toughness of enhanced concrete elements. Professional steel fixers possess specialized knowledge and abilities that guarantee the accurate installation of steel support. In summary, the advantages of specialist steel taking care of range from boosted architectural integrity to conformity with laws, making it an important part of successful construction projects.

As the building industry continues to advance, the future of steel dealing with is poised to embrace ingenious innovations and methodologies that boost efficiency and safety and security.